Often used in industrial, commercial and even residential settings, 304 stainless steel possesses the high tensile strength and durability that virtually all steels are known for, as well as having excellent forming and welding characteristics. Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

As stainless steel producers, Source 21 specializes in hard-to-find materials. We produce all tempers plus commercial and exotic stainless steel. You choose from our inventory or we can custom produce to your needs. An ISO 9001:2000 registered company; we maintain comprehensive inventories at our various US processing locations to facilitate quick shipments. Check out our website!

All Metal Sales is a leading-supplier of stainless steel tubing, stainless steel pipe, thin wall tubing, precision tubing and small diameter tubing. We focus on superior customer service, premium quality and quick turnaround times in order to best meet your needs.

More 304 Stainless Steel Tubing Manufacturers

304 Stainless Steel Tubing: Applications, Properties, and Buyer’s Guide

304 stainless steel tubing is widely recognized as a top choice for industrial, commercial, and even medical applications, thanks to its remarkable balance of corrosion resistance, durability, and workability. With a relatively high melting point of 1,400 to 1,450 degrees Celsius, Grade 304 stainless steel endures extreme temperatures and resists wear, oxidation, and environmental corrosion. These features make it a preferred material for a wide range of industries, including petrochemical, water treatment, pulp and paper, automotive, medical, dental, semiconductor, food processing, and aerospace sectors.

Why Choose 304 Stainless Steel Tubing?

When selecting tubing for demanding applications, buyers and engineers often compare materials for cost, performance, and longevity. 304 stainless steel tube stands out due to its:

- High corrosion resistance: 304 stainless steel is resistant to rust, pitting, and most chemicals, making it ideal for harsh or corrosive environments.

- Strength and durability: This alloy maintains excellent mechanical properties even at elevated temperatures and under pressure, ensuring reliable performance in structural and mechanical systems.

- Sanitary qualities: As an austenitic stainless steel, 304 is easily cleaned and sterilized, which is critical in medical, food processing, and pharmaceutical applications.

- Versatility: The tubing is available in various shapes, sizes, and finishes, meeting the exacting needs of custom projects and standard installations alike.

- Recyclability: 304 stainless steel is 100% recyclable, supporting sustainability initiatives and reducing environmental impact.

Typical applications that leverage these properties include fuel lines, architectural supports, heat exchangers, hydraulic systems, instrumentation, surgical instruments, and medical implants. Because 304 is classified as a surgical grade stainless steel, it is especially valued for use in healthcare and laboratory settings.

Understanding the Composition of 304 Stainless Steel

Originally dubbed 18/8 stainless steel for its nominal 18% chromium and 8% nickel content, 304 stainless steel’s actual composition can vary:

- Chromium: 18–20%

- Nickel: 8–18%

- Iron and Carbon: Inherent to the alloy, with low carbon to minimize carbide precipitation and improve corrosion performance.

This precise balance of alloying elements provides a unique combination of ductility, tensile strength, and resistance to intergranular corrosion. The addition of chromium forms a passive oxide layer on the steel’s surface, shielding it from environmental attack. Nickel enhances toughness and overall corrosion resistance, especially in acidic or chloride-laden environments.

304L and 304H Stainless Steel Tubing Variants

For specialized applications, 304 stainless steel tubing is also available in modified forms:

- 304L (Low Carbon): Lower carbon content increases weldability and reduces the risk of carbide precipitation during welding, making it suitable for welded structures, piping, and fabrication projects.

- 304H (High Carbon): Higher carbon content improves high-temperature strength and creep resistance, making 304H a preferred grade for heat exchangers, boilers, and furnace parts.

The choice between 304, 304L, and 304H steel tubing depends on the specific needs of your project, such as operating temperature, required weldability, and regulatory codes.

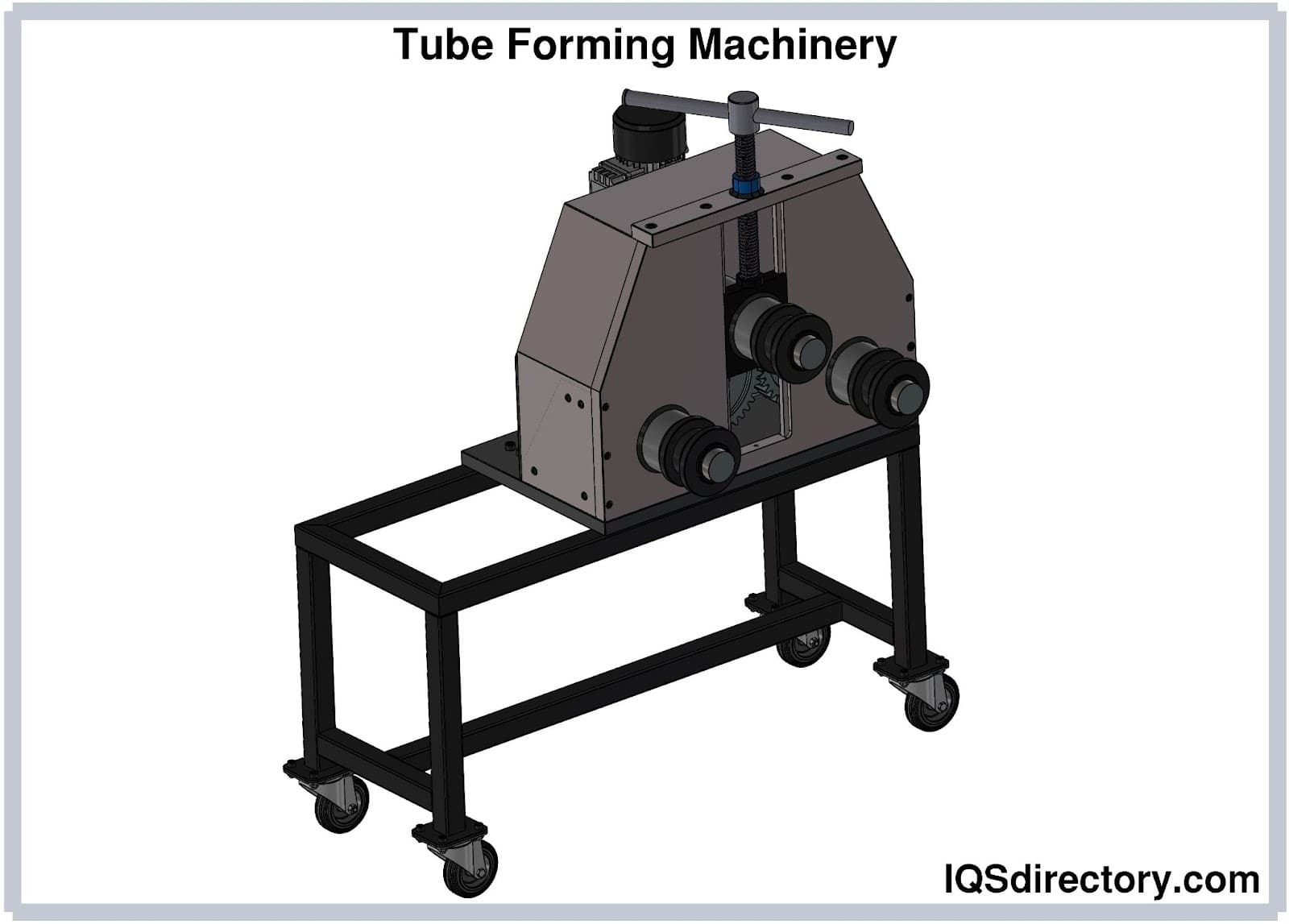

Stainless Steel Tubing Manufacturing Processes

The manufacturing method significantly influences the performance and suitability of stainless steel tubing for different applications. The primary production methods for 304 stainless steel tubing include:

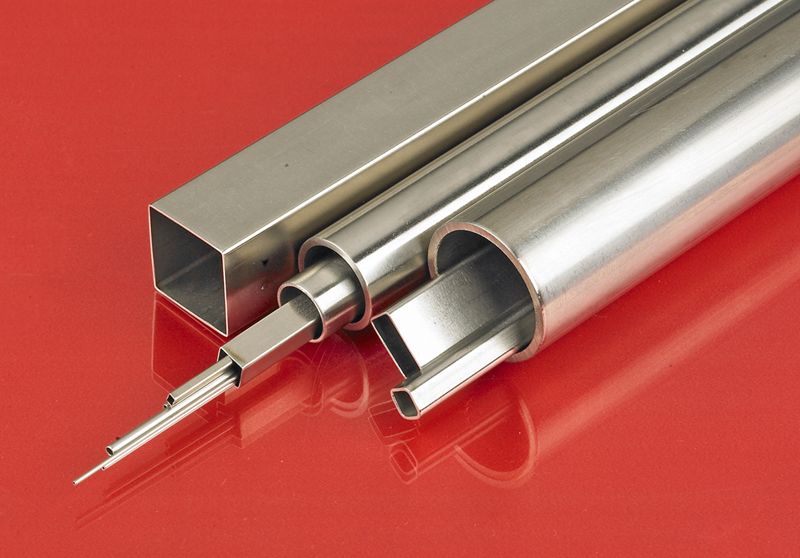

- Seamless tubing: Produced via extrusion or rotary piercing, seamless tubes have no weld seam, offering superior strength, uniformity, and corrosion resistance. They are ideal for high-pressure systems, hydraulic lines, and applications where a smooth internal surface is critical to prevent flow restrictions or contamination.

- Welded tubing: Formed by rolling stainless steel strip into a tube and welding the seam, welded tubes offer precise dimensional tolerances and are more cost-effective for many applications. Advances in welding technology have greatly improved weld quality, making welded tubes suitable for structural, architectural, and process piping uses.

- Metal spinning: This process shapes tubing by rotating a stainless steel disc at high speed while applying localized force, producing specialty tubes with custom profiles and dimensions.

When deciding between seamless and welded 304 stainless steel tubing, consider your application’s pressure requirements, tolerance for weld seams, and cost constraints. For example, seamless tubing is typically chosen for aerospace, pharmaceutical, and food processing environments, where purity and cleanliness are paramount.

Key Specifications and Buyer Considerations for 304 Stainless Steel Tubing

Choosing the right stainless steel tube involves evaluating several critical factors to ensure safe, efficient, and long-lasting performance. Common decision points include:

- Inner and outer diameter: The correct sizing is essential for fluid flow, structural integrity, and compatibility with fittings or connectors.

- Wall thickness: Thicker walls increase strength and pressure tolerance but may affect flexibility and weight.

- Length and form: Tubing is typically available in straight lengths or coils, depending on installation requirements.

- Pressure rating: Consider the maximum working pressure, which is influenced by wall thickness, diameter, and manufacturing method.

- Temperature range: 304 stainless steel maintains its properties across a wide temperature spectrum, but for extremely high temperatures, 304H may be necessary.

- Maximum bend radius: Especially important for coiled tubing or installations requiring tight turns.

- Surface finish: Options include polished, satin, or mill finishes. A smoother finish reduces risk of contamination and simplifies cleaning in sanitary applications.

- Certifications and compliance: Depending on your industry, look for tubing that meets ASTM, ASME, or ISO standards, as well as FDA or NSF certifications for food and pharmaceutical uses.

Understanding these specifications and aligning them with the demands of your project will help you select the most effective and cost-efficient solution.

Common Applications and Use Cases for 304 Stainless Steel Tubing

Due to its versatile performance profile, 304 stainless steel tubing is found in an extraordinary range of industries and functions. Where is 304 stainless steel tubing commonly used?

- Petrochemical and chemical processing: Tubing is used for transporting aggressive chemicals, solvents, and process fluids, where corrosion resistance is essential for both safety and equipment longevity.

- Water treatment and desalination: 304 stainless steel resists scaling, pitting, and biofouling, making it ideal for potable water and wastewater systems.

- Food processing and beverage manufacturing: Sanitary-grade tubing ensures product purity and simplifies cleaning, meeting stringent hygiene regulations.

- Pharmaceutical and biotechnology: The non-reactive, easily sanitized surface of 304 stainless steel supports sterile drug manufacturing environments.

- Automotive and transportation: Used for fuel lines, brake systems, exhaust components, and structural supports due to its combination of strength and resistance to vibration and corrosion.

- Architectural and structural: 304 stainless steel tubing provides structural support and aesthetic appeal in handrails, balustrades, curtain walls, and decorative features.

- Medical and dental: Surgical instruments, dental tools, and medical implants rely on the biocompatibility and sterilizability of 304 stainless steel.

- Aerospace and defense: Tubing is used in hydraulic systems, instrumentation, and structural components, where reliability and resistance to oxidation are critical.

- Semi-conductor and electronics: 304 tubing is used for ultra-clean piping systems required in chip fabrication and sensitive electronic manufacturing environments.

In each of these sectors, 304 stainless steel tubing offers the durability, performance, and regulatory compliance necessary for demanding operational conditions.

Advantages and Benefits of 304 Stainless Steel Tubing

What makes 304 stainless steel tubing the preferred choice for so many applications? Consider these key benefits:

- Exceptional corrosion resistance: Protects against rust, chemicals, and environmental factors, reducing maintenance costs and service interruptions.

- Long service life: The alloy’s durability minimizes the need for frequent replacements and repairs, offering a lower total cost of ownership compared to less robust materials.

- Hygiene and cleanliness: Smooth, non-porous surfaces can be regularly sanitized and do not harbor bacteria—a crucial benefit for food, beverage, and medical industries.

- Strength-to-weight ratio: 304 stainless steel delivers significant structural strength without excessive weight, supporting both lightweight designs and heavy-duty applications.

- Thermal and chemical stability: The alloy remains stable under wide temperature and chemical exposures, supporting use in high-heat and aggressive chemical environments.

- Ease of fabrication: 304 stainless steel tubing can be readily cut, bent, welded, or formed, supporting custom engineering solutions and quick installations.

- Sustainable and recyclable: At end of life, 304 stainless steel can be recycled, reducing both costs and environmental impact.

Ultimately, these characteristics combine to make 304 stainless steel tubing a cost-effective, high-performance choice for a vast array of fluid transport, structural, and sanitary applications.

Comparing 304 Stainless Steel Tubing to Other Stainless Steel Grades

Buyers often compare 304 stainless steel tubing to alternatives such as 316, 321, or 409 grades. How does 304 stack up?

- 304 vs. 316: While 316 stainless steel offers enhanced resistance to chlorides and marine environments due to added molybdenum, it generally comes at a higher price point. For most general-purpose, indoor, or mildly corrosive uses, 304 is sufficient and more economical.

- 304 vs. 321: 321 contains titanium, which improves high-temperature stability and resistance to intergranular corrosion during welding. Unless persistent high-heat exposure is a concern, 304 is usually more readily available and cost-effective.

- 304 vs. 409: 409, a ferritic grade, is primarily used in automotive exhaust systems and offers lower corrosion resistance compared to 304. For long-term durability and versatility, 304 remains superior.

When making a material selection, weigh environmental conditions, regulatory requirements, and total lifecycle costs. Consulting with a materials engineer or supplier can help identify the best grade for your specific needs.

Frequently Asked Questions About 304 Stainless Steel Tubing

What is the maximum operating temperature for 304 stainless steel tubing?

304 stainless steel tubing can typically withstand continuous service temperatures up to 870°C (1,600°F) and intermittent service up to 925°C (1,700°F). For applications exceeding these limits, consider 304H or other heat-resistant grades.

Is 304 stainless steel magnetic?

304 stainless steel is generally non-magnetic in the annealed condition. However, cold working or welding may induce slight magnetism.

Can 304 stainless steel tubing be welded?

Yes, 304 stainless steel is highly weldable. 304L is often preferred for welded assemblies to reduce the risk of carbide precipitation and intergranular corrosion.

What finishing options are available for 304 stainless steel tubing?

Common finishes include satin, mirror polish, brushed, and mill finish. The desired finish depends on aesthetic requirements and application—sanitary, architectural, or industrial.

How does the cost of 304 stainless steel tubing compare to other materials?

While 304 stainless steel tubing has a higher upfront cost than carbon steel or aluminum, its longevity, corrosion resistance, and reduced maintenance often deliver lower total lifecycle expenses.

How to Select the Right 304 Stainless Steel Tubing Supplier

With so many suppliers in the market, how do you choose the right partner for your stainless steel tubing needs?

- Quality assurance: Look for ISO-certified suppliers with traceable material certifications and robust quality control processes.

- Inventory and customization: Choose a supplier with a wide range of sizes, finishes, and the capability for custom fabrication or cutting to your specifications.

- Technical support: Experienced staff can help you navigate alloy selection, compliance requirements, and application engineering.

- Lead times and logistics: Reliable suppliers maintain adequate stock and can deliver quickly to meet your project timelines.

- Reputation and reviews: Investigate customer testimonials, case studies, and industry affiliations to gauge reliability and service quality.

By carefully evaluating your supplier on these criteria, you can secure high-quality 304 stainless steel tubing that meets the performance and regulatory needs of your application.

Maximizing the Value of 304 Stainless Steel Tubing

To fully leverage the benefits of 304 stainless steel tubing, consider these best practices:

- Specify requirements clearly: Communicate your exact needs—grade, dimensions, tolerance, finish, and compliance standards—to avoid costly errors or delays.

- Plan for lifecycle costs: Factor in durability, maintenance, and recyclability when comparing material options, not just initial purchase price.

- Regular maintenance: Even corrosion-resistant tubing benefits from routine inspections and cleaning, especially in aggressive environments.

- Stay updated on innovations: Advances in stainless steel metallurgy, manufacturing, and surface treatment can further enhance performance and extend service life.

Whether you’re specifying tubing for a new installation or replacing legacy systems, understanding the full capabilities, options, and best applications of 304 stainless steel tubing can help you make an informed purchasing decision, improve operational efficiency, and reduce long-term costs.

In summary, 304 stainless steel tubing offers a unique and advantageous combination of corrosion resistance, mechanical strength, sanitation, and versatility. Its widespread adoption across industries reflects its value as a reliable and cost-effective solution for fluid transport, structural support, and sanitary applications. By selecting the appropriate variant, manufacturing process, and supplier, you can ensure optimal performance for your specific application—today and well into the future.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services