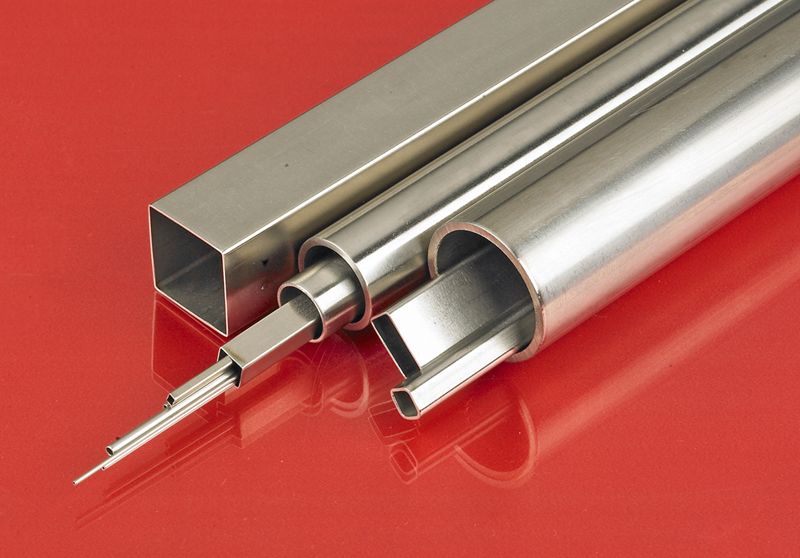

Several sizes and gauges are available for this structural/ornamental grade tube. Square stainless steel tube can be used for framing, bracing, supports, and mechanical parts, as well as for decorative trims and architectural accents because it is corrosion-resistant and weldable. In addition, steel tubes are essential to fabricating pipes for various uses, including heating and plumbing systems, highway engineering, automobile manufacturing, and even medicine. Steel tubes are made from raw materials such as iron, aluminum, carbon, manganese, titanium, vanadium, and zirconium (for surgical implants and heart valves). Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

As stainless steel producers, Source 21 specializes in hard-to-find materials. We produce all tempers plus commercial and exotic stainless steel. You choose from our inventory or we can custom produce to your needs. An ISO 9001:2000 registered company; we maintain comprehensive inventories at our various US processing locations to facilitate quick shipments. Check out our website!

All Metal Sales is a leading-supplier of stainless steel tubing, stainless steel pipe, thin wall tubing, precision tubing and small diameter tubing. We focus on superior customer service, premium quality and quick turnaround times in order to best meet your needs.

More Stainless Steel Square Tubing Manufacturers

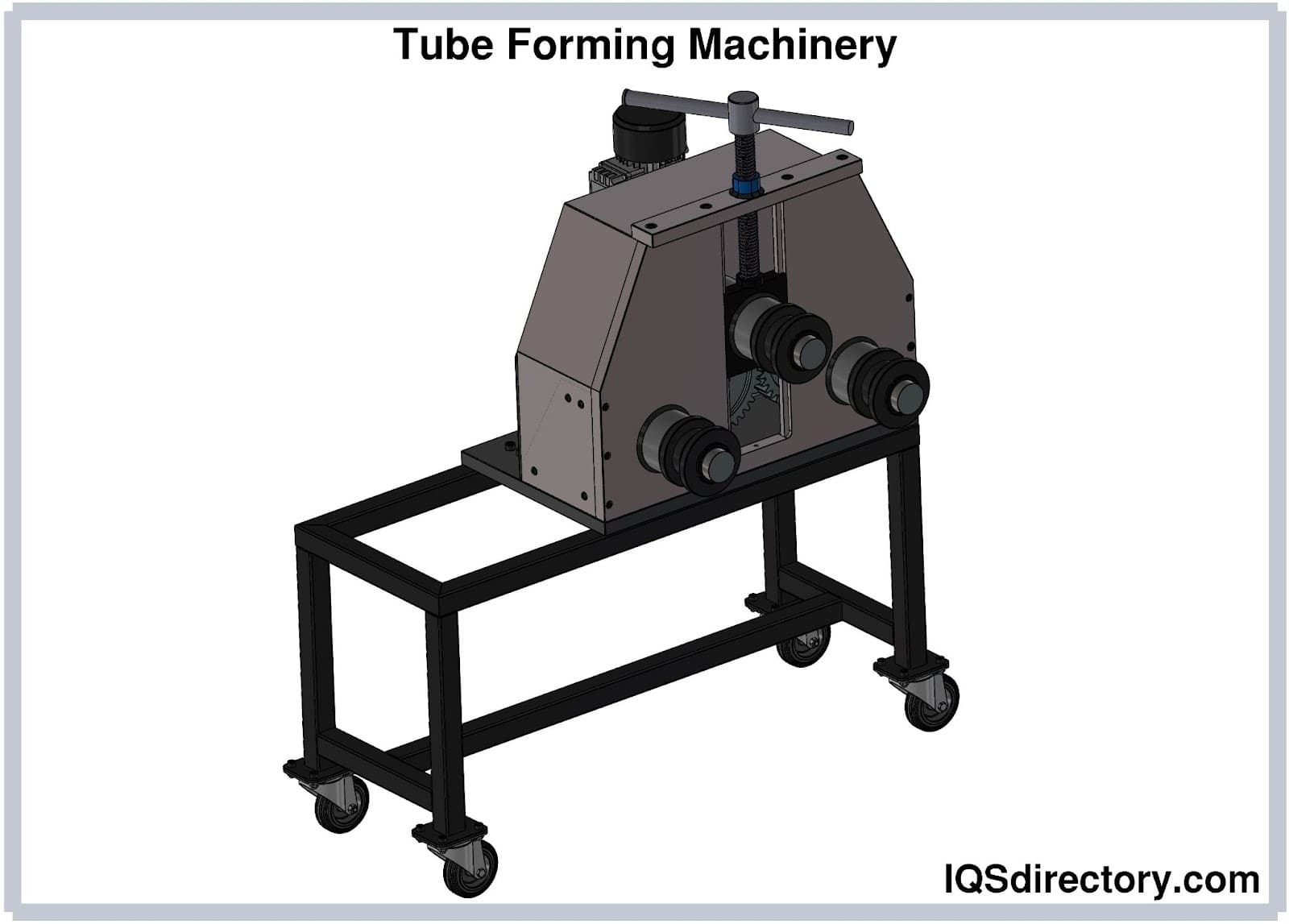

Manufacturing Process of Steel Square Tubes

Steel square tubing is a versatile and durable product widely used across industries for its combination of strength, corrosion resistance, and clean lines. Understanding the manufacturing process of steel square tubes is crucial for buyers, engineers, architects, and fabricators seeking reliable materials for construction, manufacturing, and industrial applications. Whether you're researching stainless steel square tubing for its mechanical properties or evaluating it for specific engineering projects, knowing how it's made can help you make more informed purchasing decisions.

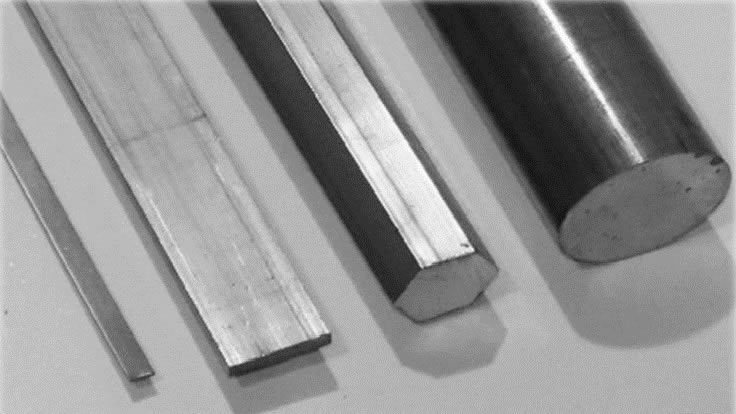

Transformation of Raw Steel Into Tubing Materials

Raw steel must first be transformed into weldable materials such as ingots, blooms, slabs, or billets to make steel tubes. The journey begins with raw iron ore and coke, which are combined and melted in a blast furnace. The resulting molten steel is the foundation for a range of steel products, including square tubing, rectangular tubing, and round tubes. This molten steel is poured into molds to form steel ingots, which are then processed further to meet the dimensional and mechanical requirements of industrial steel tubing.

Rolling and Shaping of Steel

Molten steel is produced by melting iron ore and coke—a carbon-rich material derived from heated coal—into a liquid in a furnace and blasting it with oxygen. This substance is cooled into steel ingots, which are substantial castings molded between rollers under intense pressure. Some ingots are run through steel rollers, which stretch them into thinner, longer pieces to produce blooms, which are intermediates between steel and iron. Additionally, they are rolled between stacked rollers that shape the blooms into rectangular-sectioned steel pieces known as slabs. These processes are vital for producing the precise tolerances and surface finishes required for precision steel tubing and structural applications.

Coining and Billet Formation

In a procedure known as coining, further rolling mechanisms flatten blooms into billets. These are even longer and thinner pieces of metal with round or square cross-sections. Flying shears cut the billets at exact angles to enable stacking and seamless pipe formation. Slabs are thinned into skelp, which are narrow strips of ribbon up to 0.25 miles (0.4 kilometers) in length, after being heated to a temperature of around 2,200 degrees Fahrenheit (1,204 degrees Celsius), making them pliable. The steel is then cleaned with sulfuric acid tanks, followed by cold and hot water, before being transferred to facilities that make pipes. This stage is crucial for ensuring the high-quality surface required for architectural stainless steel tubing and aesthetic installations.

Welding and Seamless Tube Production

For welded pipes, skelp is unwound and put through rollers on an unwinding machine to cause the edges to curl and form pipes. Before being tightened by a high-pressure roller, the ends are sealed together by welding electrodes using an electric current. This produces an electrically welded seam that is robust and reliable, making it ideal for structural and mechanical tubing. This method has a maximum production rate of 1,100 feet (335.3 meters) of pipe per minute, supporting high-volume demands in the construction and manufacturing industries. For seamless tubing, square billets are stretched with a hole in the middle during the high-pressure rolling and heating process. The pipe is then pierced in rolling mills to achieve the correct thickness and shape, providing superior strength and uniformity required for high-pressure and critical applications.

Finishing: Straightening, Threading, and Galvanizing

Straightening, threading (which involves carving narrow grooves into the ends of pipes), galvanizing, or any other additional processing required for the pipe's intended use may be done. Galvanization typically comprises electrochemical and electrodeposition procedures of zinc coatings to protect the metal from corrosive substances like salt water. Galvanized square tubing is commonly chosen for outdoor, marine, and corrosive environments where enhanced rust resistance is essential. These value-added processes can also include cutting, deburring, and polishing, depending on whether the final application is structural, ornamental, or for fluid transfer.

The Science and Benefits of Galvanization

The method prevents hazardous oxidizing substances in the air and water. Zinc reacts with oxygen as an anode to produce zinc oxide, which combines with water to produce zinc hydroxide. When exposed to carbon dioxide, these zinc hydroxide molecules transform into zinc carbonate. Finally, zinc is shielded by a thin, impermeable, insoluble coating of zinc carbonate. The result is a long-lasting, low-maintenance tubing solution that withstands harsh industrial conditions and reduces lifecycle costs for end users.

Since hot-dip weakens the base metal, electro galvanization, a thinner variant, is typically employed on auto parts that need rust-proofing paint. When stainless components are galvanized with carbon steel, stainless steel is produced. Stainless steel square tubing combines the anti-corrosive properties of stainless with the structural integrity of carbon steel, making it a preferred choice for environments where hygiene, durability, and appearance are important.

Applications of Stainless Steel Square Tubing

Stainless steel square tubing is a highly sought-after product due to its blend of mechanical strength, corrosion resistance, and modern appearance. Its versatility makes it a go-to material for architects, builders, engineers, and manufacturers seeking reliable solutions for a wide array of uses. But what are the most common and high-value uses for this type of tubing, and why does it remain a top choice in so many sectors?

Residential and Commercial Architecture

- The ideal choice for home entry gates is square tubes. The sleek square tube's beauty and finish, not to mention its practicality, are surely desired by homeowners wishing to finish their ultramodern or contemporary homes. Of course, any residential gate will typically increase the property's protection, but square tubing ups the ante by adding a decorative feature. For instance, cold-formed square tubes can be changed into many designs because of their great ductility and malleability. In addition, they can be equipped with access control, turnstiles (for commercial buildings), and other contemporary home solutions like automatic gate openers.

Structural Engineering and Construction

- A network of building columns can be created using square tubes, which are structural steel or metal goods. Since square tubes can support a variety of loads despite the material variance, this is one of its best applications. Contrary to popular opinion, the square tubing's hollow design may handle such loads. Due to the tube's small weight, it is preferable to other solid-shaped building materials of a similar nature. The tubes now have a superior strength-to-weight ratio that is on par with that of PVC, wood, or pure concrete. Square tubes can be used to create full-fledged column constructions on their own, but they can also be used in conjunction with concrete to fortify the framework and increase tensile strength. Due to its semi-brittle nature, concrete benefits from using square metal tubing by being better able to withstand physical impacts while lowering construction costs.

Industrial and Manufacturing Applications

- Stainless steel square tubing is widely used in industrial equipment frames, support structures, and machinery guards, where its strength and corrosion resistance are vital. Its uniform geometry and consistency make it ideal for automated fabrication and assembly lines. In industries such as food processing, pharmaceuticals, and chemical manufacturing, the hygienic properties of stainless steel square tubing are critical for maintaining safety and cleanliness.

- In agricultural environments, square steel tubing is used for fencing, livestock pens, and greenhouse frames, offering long-term durability against weather and corrosive chemicals. Its adaptability allows for easy modification and repair, extending the useful life of agricultural infrastructure.

Transportation and Automotive Uses

- Automotive manufacturers use stainless steel square tubing in chassis construction, roll cages, and exhaust systems due to its strength, lightweight properties, and resistance to corrosion and heat. Its precision and reliability are crucial for safety-critical applications in vehicles, trailers, and transport containers.

- In marine and aerospace industries, stainless steel tubing is selected for its ability to resist saltwater, chemicals, and harsh weather, ensuring long service life and safety in demanding environments.

Furniture, Décor, and Artistic Installations

- Modern furniture makers and interior designers favor stainless steel square tubing for its clean lines, contemporary appeal, and ability to support innovative designs. It is found in tables, chairs, shelving, railings, and decorative installations, where strength and style must coexist. The malleability of stainless steel allows for custom fabrication, enabling architects and artists to realize unique projects.

Why Choose Stainless Steel Square Tubing?

When deciding between different types of metal tubing, buyers often consider stainless steel square tubing for its unique set of advantages. But what makes it stand out compared to alternatives like carbon steel tubing, aluminum tubing, or PVC?

- Corrosion Resistance: Stainless steel contains chromium, which forms a passive oxide layer, protecting the tube from rust, oxidation, and chemical attack. This feature makes it an excellent choice for outdoor and marine applications, as well as environments with high humidity or exposure to chemicals.

- Strength-to-Weight Ratio: The hollow, square design provides high rigidity and load-bearing capacity while keeping the weight relatively low. This ratio is especially important for structural applications, where reducing overall weight can lead to significant savings in transportation, installation, and foundational requirements.

- Aesthetic Appeal: Stainless steel square tubing offers a modern, polished appearance that enhances architectural and decorative projects. Its ability to accept a variety of finishes—from brushed to mirror polish—makes it suitable for both utilitarian and high-end design applications.

- Fabrication Versatility: Stainless steel is readily cut, welded, machined, and formed, allowing for easy adaptation to complex project needs. This adaptability opens the door to custom solutions, whether for industrial automation, art installations, or precision engineering.

- Low Maintenance: Unlike other materials that require painting, sealing, or frequent replacement, stainless steel square tubing stands the test of time with minimal upkeep, reducing long-term maintenance costs and downtime.

- Hygienic and Non-porous: For food, beverage, and pharmaceutical processing, the non-porous nature of stainless steel means it resists bacterial growth and is easy to sanitize, meeting stringent health and safety regulations.

- Sustainability: Stainless steel is fully recyclable, and many manufacturers use a high percentage of recycled content in their tubing, supporting green building initiatives and sustainable manufacturing practices.

How to Choose the Right Stainless Steel Square Tubing

Selecting the right stainless steel square tubing for your application involves considering several important factors. Here are some common buyer questions and decision points to help guide your selection:

- What grade of stainless steel is best? Common grades include 304, 316, and 201. 304 stainless steel is highly versatile and suitable for most applications, while 316 offers enhanced corrosion resistance for marine and chemical environments. Lower-cost 201 stainless can be used where moderate corrosion resistance is acceptable.

- What are the dimensional requirements? Determine the required outside dimensions, wall thickness, and length. Standard sizes are readily available, but custom fabrication is possible for unique project needs.

- What surface finish is required? Consider whether a polished, brushed, or mill finish is needed for aesthetics or functionality. Polished finishes are popular for architectural and decorative uses, while mill finishes may suffice for structural or concealed applications.

- Will the tubing be exposed to harsh environments? If so, opt for higher grades and additional coatings such as passivation or galvanization to maximize lifespan and performance.

- What fabrication processes will be used? Ensure that selected tubing is compatible with planned cutting, welding, bending, or machining operations to avoid costly complications during installation.

- What certifications or standards are necessary? For critical applications, confirm that the tubing meets relevant ASTM, ASME, or ISO standards for material composition, tolerances, and performance.

By carefully answering these questions, buyers can align their tubing selection with project requirements, regulatory needs, and budget constraints.

Choosing the Right Stainless Steel Square Tubing Supplier

To make sure you have the most productive outcome when purchasing stainless steel square tubing from a stainless steel square tubing supplier, it is important to compare at least 4 to 5 companies using our stainless steel square tubing directory. Each stainless steel square tubing supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each stainless steel square tubing company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel square tubing businesses with the same message.

Key Factors When Evaluating Stainless Steel Tubing Suppliers

- Product Range: Does the supplier offer a comprehensive inventory, including various grades, sizes, and finishes of stainless steel square tubing? A broad product range ensures you can source all your needs from one vendor, saving time and reducing costs.

- Quality Assurance: Look for suppliers with rigorous quality control practices and certifications. Reputable suppliers provide material test reports, traceability, and compliance with industry standards such as ASTM and ISO.

- Customization and Fabrication Capabilities: Leading suppliers can provide custom cutting, drilling, bending, or finishing services, streamlining your project and reducing lead times.

- Lead Time and Delivery: Reliable suppliers maintain large inventories and efficient logistics networks to support just-in-time delivery and minimize downtime on your job site or production line.

- Technical Support: Top stainless steel tubing suppliers offer engineering and technical assistance, helping you select the right tubing, troubleshoot fabrication challenges, and ensure code compliance.

- Competitive Pricing: Compare pricing among suppliers, but also consider additional value such as customer service, after-sales support, and flexible payment options.

Frequently Asked Questions About Stainless Steel Square Tubing

What are the standard sizes and wall thicknesses for stainless steel square tubing?

Standard sizes typically range from ½ inch to 12 inches in outside dimension, with wall thicknesses from 0.028 inch (0.7 mm) up to 0.500 inch (12.7 mm) or more. Tubing is available in metric and imperial sizes, and custom sizes can be produced for specialized requirements.

How is stainless steel square tubing different from rectangular tubing?

While both products share similar manufacturing processes and mechanical properties, square tubing features equal sides, making it ideal for applications requiring uniform strength and appearance in both axes. Rectangular tubing, with its elongated shape, is preferred in situations where directional strength or space optimization is needed.

What finish options are available for stainless steel square tubing?

Finishes include mill (as rolled), brushed, polished (mirror), and custom surface treatments such as passivation or powder coating. The chosen finish affects not only appearance, but also corrosion resistance and ease of cleaning.

Is stainless steel square tubing weldable or machinable?

Yes, stainless steel tubing is readily weldable and machinable using appropriate techniques and tools. Selection of the right filler material, shielding gas, and cutting tools ensures optimal joint strength and surface quality.

What industries most commonly use stainless steel square tubing?

Industries include construction, architecture, transportation, manufacturing, food and beverage processing, pharmaceuticals, chemical processing, agriculture, and energy. Its versatility, durability, and hygiene make it a staple material in both heavy industry and high-design environments.

How do I calculate the weight of stainless steel square tubing?

Weight can be calculated using the formula: [(Outside Width – Wall Thickness) x Wall Thickness x 2] x Length x Density of Stainless Steel (typically 0.289 lbs/in³ or 7.85 g/cm³). Many suppliers offer online calculators to simplify this process.

Conclusion: Making the Most Informed Stainless Steel Square Tubing Purchase

Whether you’re an architect seeking a clean, modern aesthetic, an engineer demanding unmatched strength and corrosion resistance, or a buyer looking for cost-effective, long-lasting materials, stainless steel square tubing delivers on all fronts. By understanding the manufacturing process, exploring the wide range of applications, and carefully evaluating suppliers, you can ensure your project benefits from the unique advantages of this reliable, high-performance material. From residential gates and structural columns to industrial machinery and artistic installations, stainless steel square tubing continues to set the standard for quality, versatility, and value in today’s marketplace.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services