A hypodermic needle is a type of needle commonly used with a syringe to inject substances or take substances from the body, as well as the rapid delivery of liquids in both medical and non-medical applications. Most hypodermic needles are designed for single use because they are hard to decontaminate and need sharpening after repeated use. Some of the wide-ranging applications for hypodermic needle tubing are found in industries such as dental, automotive, petrochemical, and semiconductor industries. Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

As stainless steel producers, Source 21 specializes in hard-to-find materials. We produce all tempers plus commercial and exotic stainless steel. You choose from our inventory or we can custom produce to your needs. An ISO 9001:2000 registered company; we maintain comprehensive inventories at our various US processing locations to facilitate quick shipments. Check out our website!

All Metal Sales is a leading-supplier of stainless steel tubing, stainless steel pipe, thin wall tubing, precision tubing and small diameter tubing. We focus on superior customer service, premium quality and quick turnaround times in order to best meet your needs.

More Hypodermic Needle Manufacturers

In addition, hypodermic needle tubing is used in applications ranging from medical instruments and dental implants to hydraulic systems, fuel lines, and engine conduits. In the industrial manufacturing industry, hypodermic needles are most commonly utilized in the application of precise amounts of various types of liquids and pastes including lubricants and adhesives.

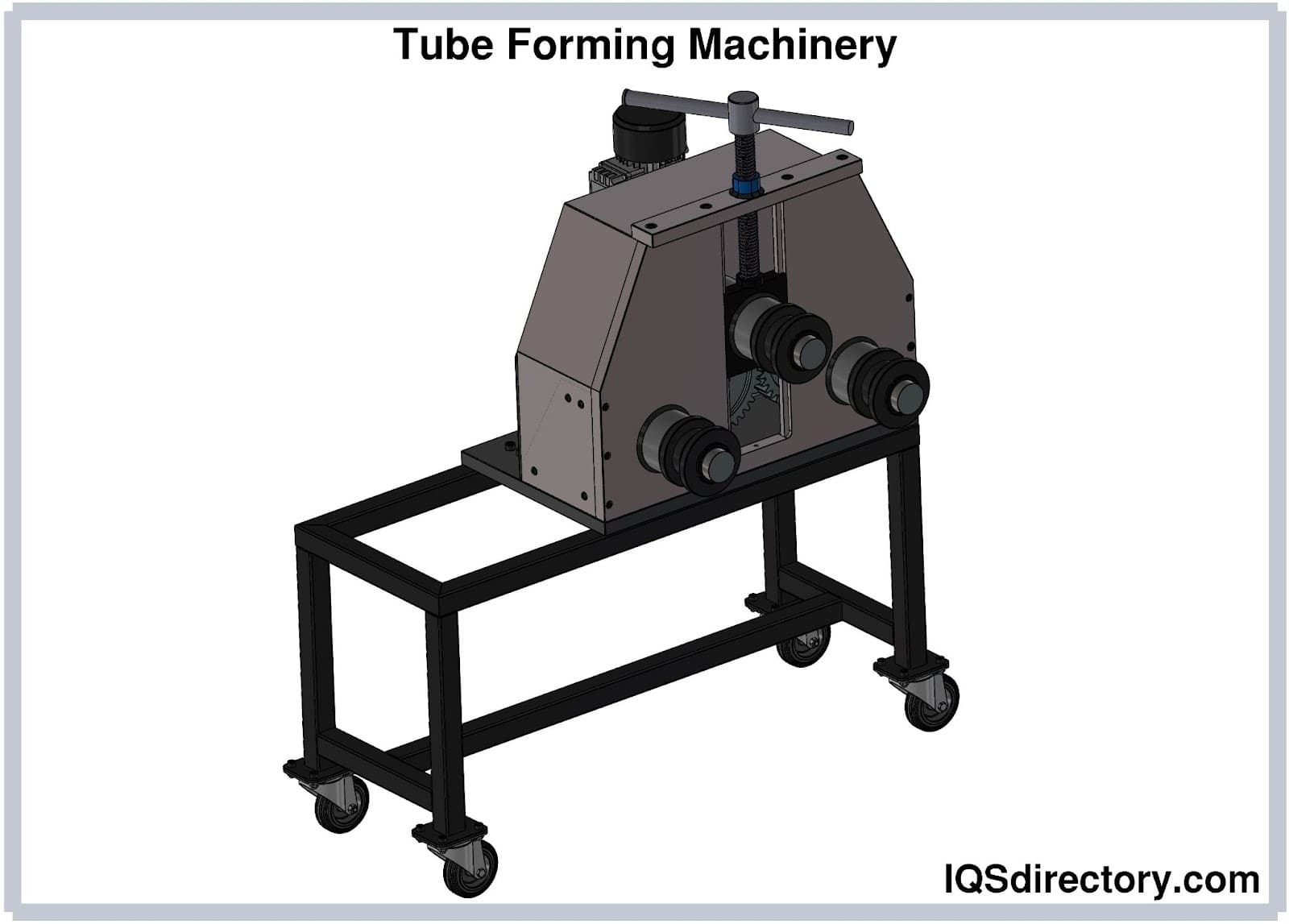

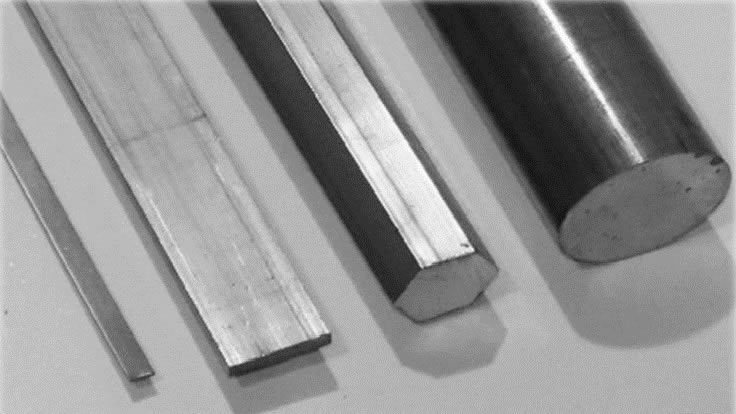

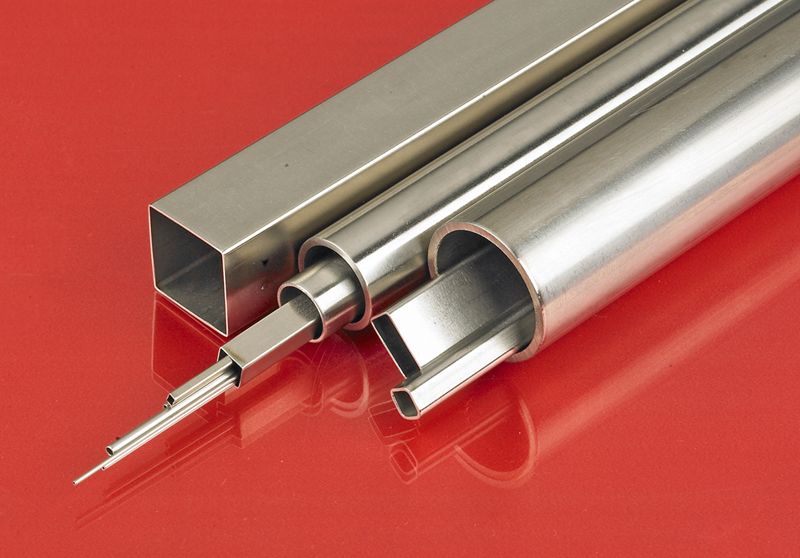

Hypodermic needle tubing is constructed through welding or seamless tubing procedures. Welding involves roll forming stainless steel and connecting the formed portions along a seam through fusion. Seamless tubing, in comparison, involves the creation of stainless steel tubing by piercing a round blank. Welding achieves a higher degree of precision without secondary operations, although the degree of precision required depends on the particular industrial application.

Metal spinning is a "cold worked" metal fabrication technique which is similar to a potter forming clay, except that a metal spinner uses a flat round disc of sheet metal which is rotating on a spinning lathe. The metal spinning process is limited, however, to the making of concentric shapes such as tubes. From these stainless steel tubes, a process known as tube drawing is performed.

Tube drawing is a metalworking process that is used in order to size the stainless steel tube by shrinking a large diameter tube into a smaller one, and then drawing the tube through a die. This process is used in the production of hypodermic tubing because it provides high quality with precise dimensions, good surface finish, and the additional strength provided by cold working.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services