Stainless steel tubing is a long-lasting material used for structural applications. Stainless steel tubing is versatile and useful in many industrial applications. Manufacturers can design tubing in a range of diameters. It’s strength and corrosion resistance make stainless steel tubing a great material for industrial construction work. Read More…

Cada Stainless & Alloys has the stainless steel tubing that you need. We also specialize in the supply of stainless steel strips and coils, providing many finishing options, processing options, and other customization options.

As stainless steel producers, Source 21 specializes in hard-to-find materials. We produce all tempers plus commercial and exotic stainless steel. You choose from our inventory or we can custom produce to your needs. An ISO 9001:2000 registered company; we maintain comprehensive inventories at our various US processing locations to facilitate quick shipments. Check out our website!

All Metal Sales is a leading-supplier of stainless steel tubing, stainless steel pipe, thin wall tubing, precision tubing and small diameter tubing. We focus on superior customer service, premium quality and quick turnaround times in order to best meet your needs.

More Stainless Steel Tube Manufacturers

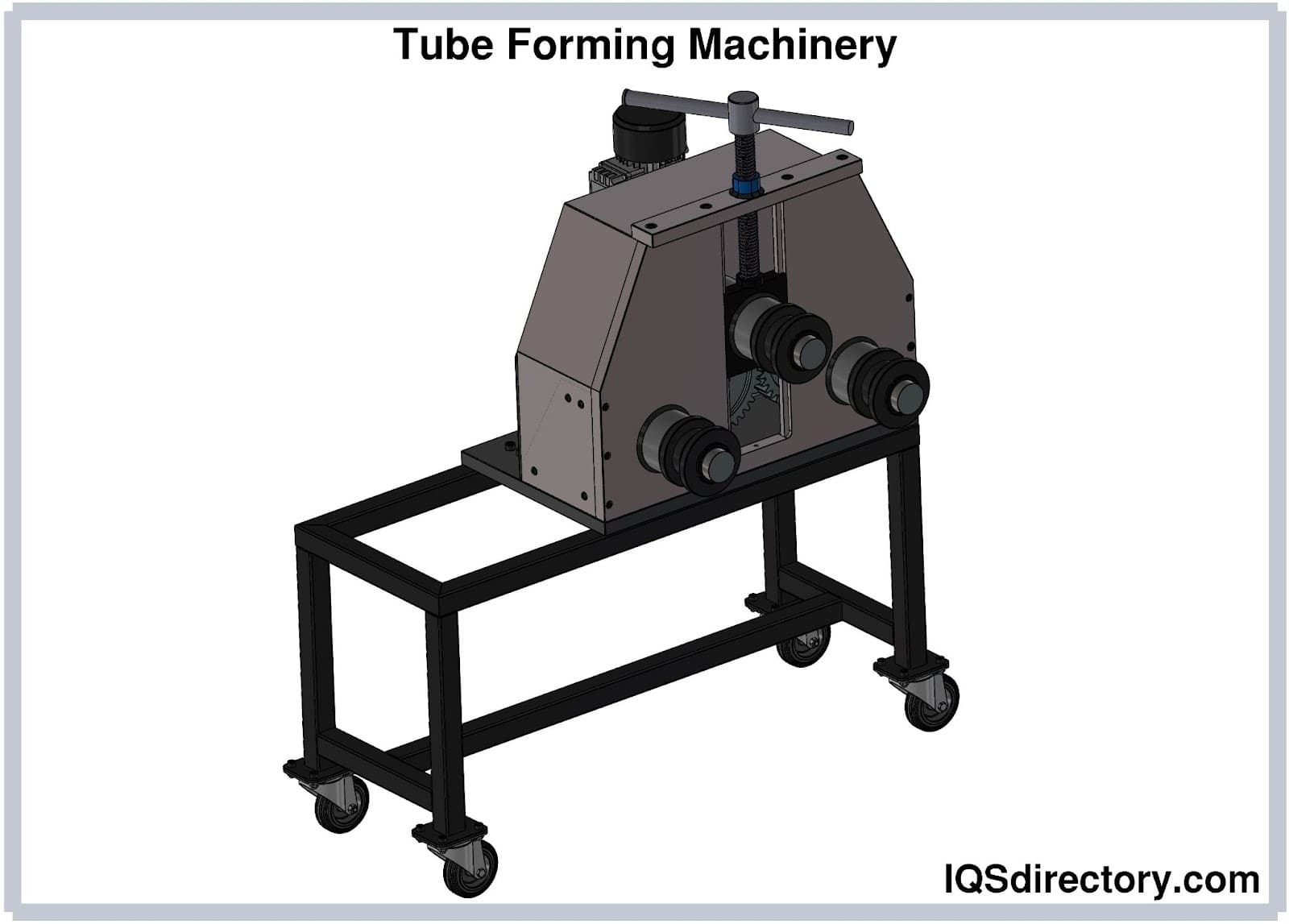

How Stainless Steel Tubes Are Manufactured

Stainless steel coils are manufactured on a tube mill through rolling and welding. First, manufacturers use high-frequency laser welding to join the strip edges. To produce a high-quality weld, strip edges may be prepped beforehand. Next, a finishing process using scarfing, sanding, or bead rolling removes the weld beads on the interior and exterior of the tube.

The stainless steel tubes are cut to the required lengths following market demand. Next, the tubes are cleaned and given a heat treatment. Heating decreases the stress created during the welding and forming procedures. The heat treatment is performed in a continuously rolling hearth furnace. The furnace often uses temperature recorders and controllers. Once the stainless steel pipes and tubes have undergone heat treatment, they are straightened and pickled to remove surface scales.

The finished pipes or tubes are marked using automated ink jet marking equipment. Before being sent to stainless steel pipe exporters, the pipe or tube is marked with the material grade, heat number, size, and stamp of a third-party inspection. The final stainless tubes or pipes will undergo rigorous testing and quality control. The appropriate shipping and packaging follow. Numerous stainless steel pipe applications use these pipes and tubes.

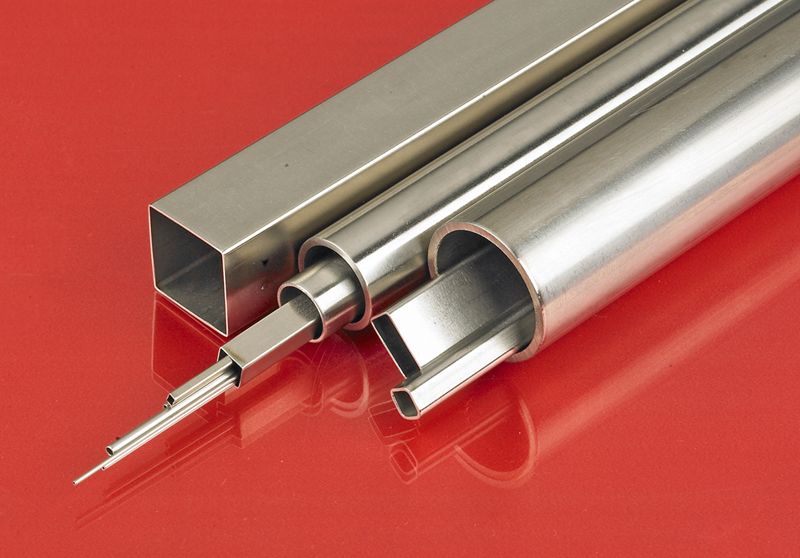

Types of Steel Tubing

A single stainless steel tube may be seamless or not, have a variable radius, length, or wall thickness, and be polished or unpolished. Below are the different types of stainless steel tubes.

304 and 316 Stainless Steel Tube

304 or 316 stainless steel tubing is frequently used to transport fluids and gases. It is made of a particular steel alloy. Since 304 stainless steel has excellent tensile endurance and strength, it’s used in industrial, commercial, and even residential applications.

Corrugated Stainless Steel Tubing

A corrugated stainless steel tube is a hollow, multi-layered cylindrical tube that can transport gases instead of standard steel piping.

Hypodermic Tubing

Hypodermic tubing is a common method for delivering medication under the skin. When used for injection or removal, hypodermic tubing facilitates a rapid flow of fluids.

Stainless Steel Pipes

A stainless steel pipe is a long stainless steel tube that moves materials like water, gas, and oil.

Applications for Steel Tubing

Transportation

Steel tubing is a common part of the engines and fuel lines in everything from cars and trucks to trains and airplanes. Steel tubes convey gas, oil, steam, and smoke more often than any other material. In addition, tubing is used in exhaust pipes, muffler components, chemical delivery, and even extremely tough items like roll cages.

Industrial

Steel tubing is used in industrial applications to transport liquid wastes, gases, and water. For example, steel tubes are often used as a component in conveyor belts, hydraulic lifts, mills, and many other industrial devices. In addition, at least a couple of the popular appliances in homes are almost certainly constructed from steel tubes.

Clinical

Steel tubing is crucial for medical equipment. Medical steel must be long-lasting and high quality to provide the best patient care. Surgical equipment routinely uses steel tubing; many implants must be tube-shaped to fit bone. Stethoscopes are made using particular types of steel tubing. Additionally, beds, wheelchairs, IV stands, and various other items contain tubular steel.

Aerospace and Military

These applications usually entail moving fluids and must be extremely resistant to adverse weather. These constructions need much more space strength than they would on Earth. Steel tubes may be used in anything from the landing gear and motor shafts to the exhaust stacks. The military routinely constructs vehicles and weapons out of tubular steel.

Advantages of Stainless Steel Tubes

Stainless steel tubes have many advantages over conventional metals. In addition to being strong, stainless steel tubing has the following advantages: it can be formed into a variety of grades and tube radii; it can transport cold or hot liquids and gases; it is resistant to deterioration when exposed to most chemicals, and it can be formed at a lower cost for lower pressure systems.

Choosing the Correct Stainless Steel Tube Company

To make sure you have the most beneficial outcome when purchasing stainless steel tubes from a stainless steel tube company, it is important to compare at least 5 manufacturers using our list of stainless steel tube companies. Each stainless steel tube company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each stainless steel tube business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple stainless steel tube companies with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services